FL ball mill for cement grinding. ... absorption and grinding efficiency. For special applications a classifying shell lining may be supplied for fine grinding

Ball Mill. A high efficiency and energy saving ball mill with rolling bearing. Get Price; High Spiral Classifier. Classifying equipment takes use of the ...

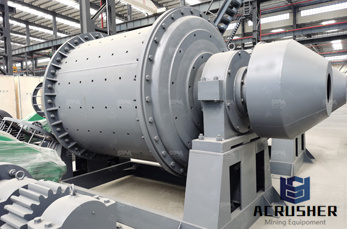

Ball mill is a kind of very important equipment in mining, metallurgy, chemical and some other industries. Many customers wonder how to improve the grinding ...

What is the effect of low ball % full on grinding efficiency?One of our clients is thinking of the future and has bought a ball mill that will be the right size ...

Maximize your grinding efficiency ... • Ball mills ... helps you improve mill availability and grinding efficiency.

factors affecting the ball mill efficiency manufacturer in Shanghai, China. factors affecting the ball mill efficiency is manufactured from Shanghai Xuanshi,It is the ...

IMPLEMENTING STRATEGIES TO IMPROVE MILL CAPACITY ... and efficiency of wet screening machines vs. length or area. ... followed by Secondary Ball Mill

Factors Affecting the Efficiency of Ball Mill College Essays ... Ball mill is the key equipment for grinding after the crush process, and it is widely used in the ...

Ball mills are usually the largest consumers of energy within a mineral concentrator. ... media in the mill by looking at the mill grinding efficiency. At

Ball charges: This calculator gives the surface and the average weight of the ball charges. It gives also a rough interpretation of the ball charge efficiency:

Factors Affecting the Efficiency of Ball Mill College Essays ... Ball mill is the key equipment for grinding after the crush process, and it is widely used in the ...

Hongke Machinery is specialized in making ball mill,ball mill prices,ball,ball mill efficiency, has almost reached the international advanced level ...

Ball mill A typical type of ... However, the smaller the rods, the larger is the total surface area and hence, the greater the grinding efficiency. Autogenous mill

Six Factors that Affect Ball Mill Zhongyu Heavy Industry Working efficiency of ball mill is affected by combined actions like water volume, grinding medium, raw ...

ball mill efficiency vs temperature effect of temperature in grinding in a ball mill YouTube 11 Jun 213 When the internal temperature of the cement ball mill .

Relationship of Media Size and Grinding Efficiency of Ball Mill. The ball mill crushes materials through the impact and grinding effect of the grinding media. In this process, the steel ball is used a medium of energy to transform the outside energy to the crushing forces, thus completing the materials crushing process.

Effect of ball size and powder loading on the milling efficiency of a laboratoryscale wet ball mill

To achieve a reasonable efficiency with ball mills, ... This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between ...

Mar 08, 2013· calculation of ball mill grinding efficiency. dear experts . please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill.

Addition of pebbles to a ballmill to improve grinding efficiency S Nkwanyana and B Loveday (1) PRESENTED AT COMMINUTION ''16, MINERALS ENGINEERING INTERNATIONAL ...

for Accident Prevention Design for Energy Efficiency ... What is ball milling? A ball mill is a type of grinder used to grind materials

Improving The Efficiency Of Fine Grinding ... efficiency of stirred mills compared to ball mills is ... Efficiency Of Fine Grinding – Developments In ...

Grinding Efficiency + Pdf. ... ball mill grinding efficiency | Solution for Mining Quarry. ball mill pdf. COMPARISON OF A LABORATORY TOWER AND TUMBLING BALL ...

A ball mill generally loses its grinding efficiency remarkably at fine grinding. This is because fine particles from ground materials agglomerate and adhere to the ...

WhatsApp)

WhatsApp)